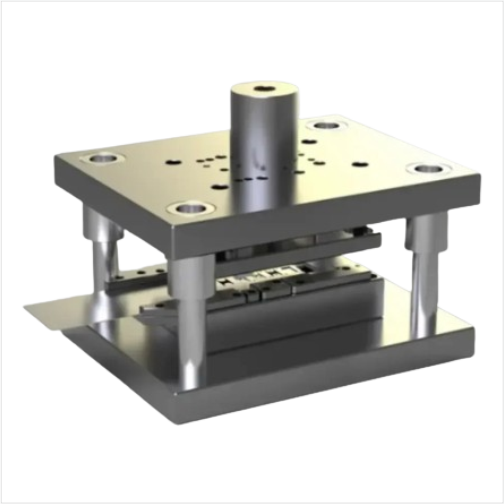

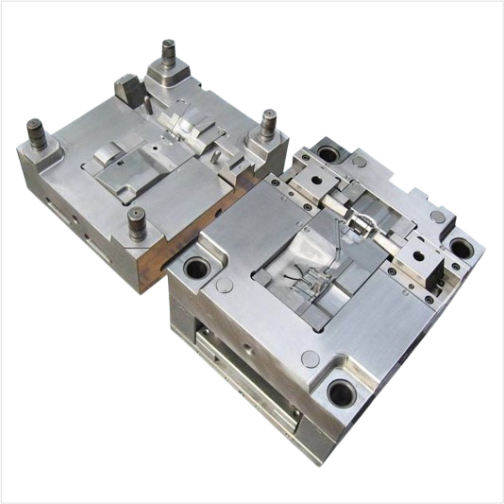

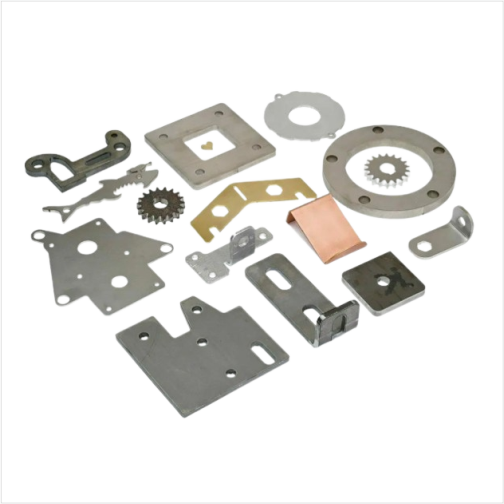

S.S. Engineering Works has been a leading manufacturer in the engineering sector since 2010 under the leadership of Mr. Sushil Vishwakarma, specializing in the production of high-quality mould dies for various applications. Located in Vadodara, Gujarat, we serve a diverse clientele across industries, notably in plastic, automobile, engineering, chemical, and pharmaceuticals. Our expertise encompasses sheet metal dies, injection molding, and extrusion lines, as well as the development of specialized machines for the chemical and pharmaceutical industries.

SPECIALISED IN SHEET METAL DIES & PLASTIC MOULD

S.S. Engineering Works stands as a trusted partner in engineering solutions, known for our integrity, innovation, and commitment to excellence. We are excited to continue our journey of growth and to cater to our clients’ evolving needs with top-tier engineering products and services. Our success is driven by a dedicated team of professionals with extensive experience in engineering and manufacturing. From design engineers to production specialists, our staff is committed to continuous improvement and excellence in every project.

Our Mission

To offer superior engineering products and services tailored to our customers’ needs, leveraging advanced technology and skilled craftsmanship to ensure excellence, reliability, and customer satisfaction.

Our Vision

S.S. Engineering works is to be recognized as a premier provider of innovative engineering solutions and high-quality mould dies, contributing to the success and efficiency of our clients’ operations.

Quality Assurance

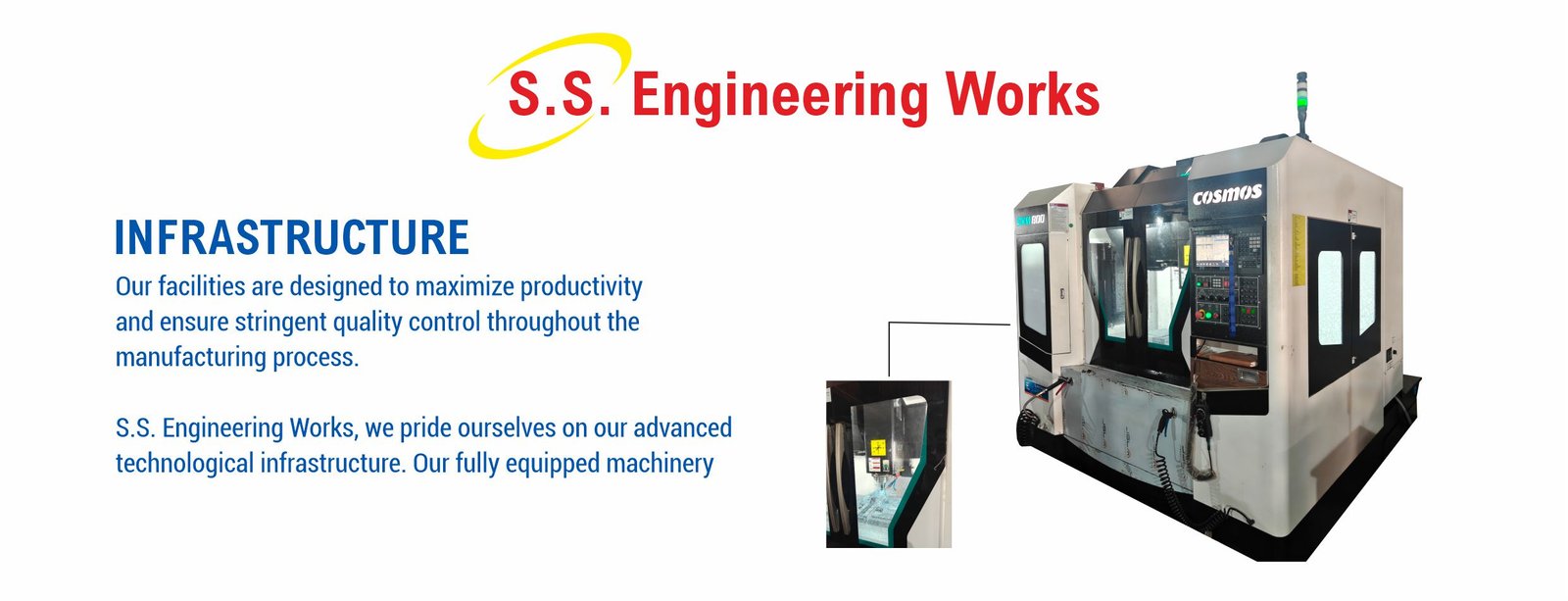

Quality is at the forefront of our operations. We adhere to rigorous quality standards, from material selection to final inspection. Our team of skilled engineers & technicians is committed to delivering products.

SOME OF OUR VALUABLE CLIENTELE

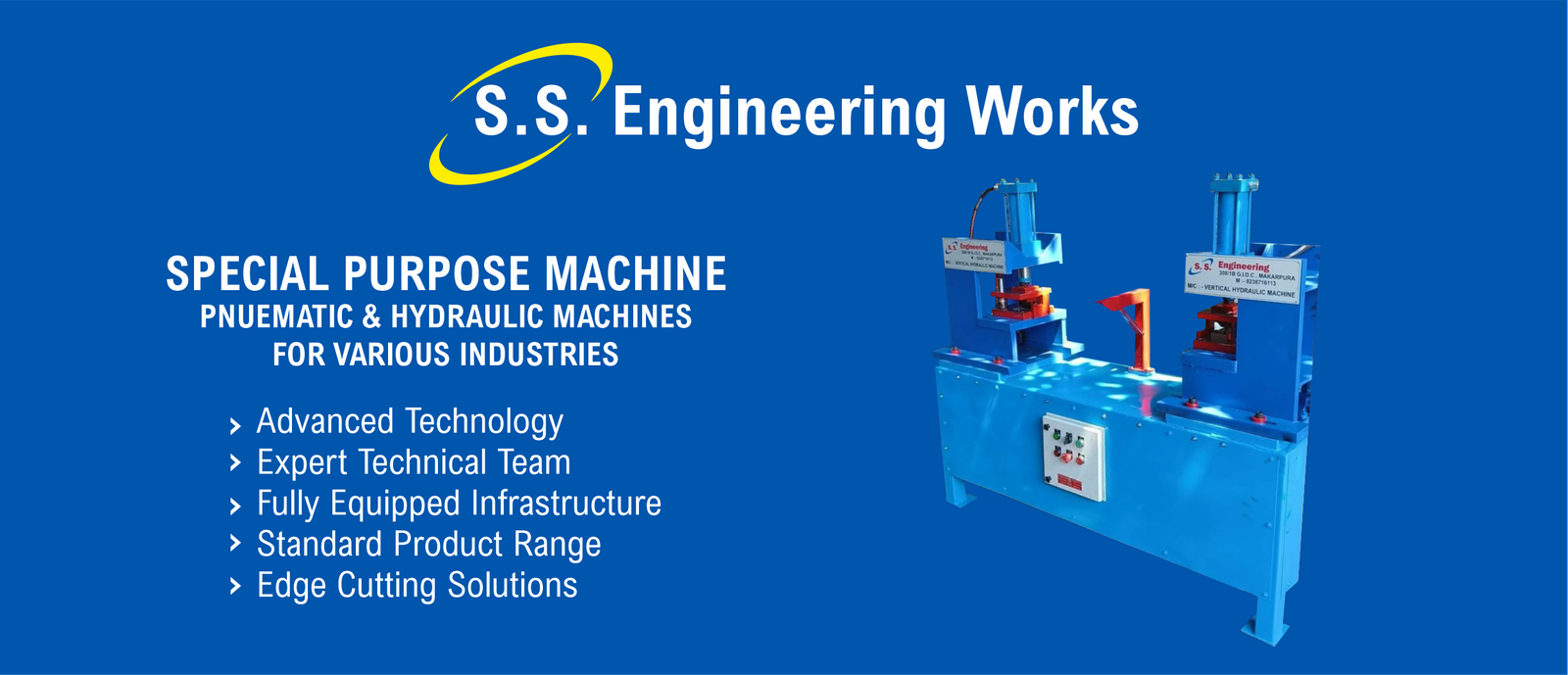

WHY CHOOSE S.S. ENGINEERING WORKS?

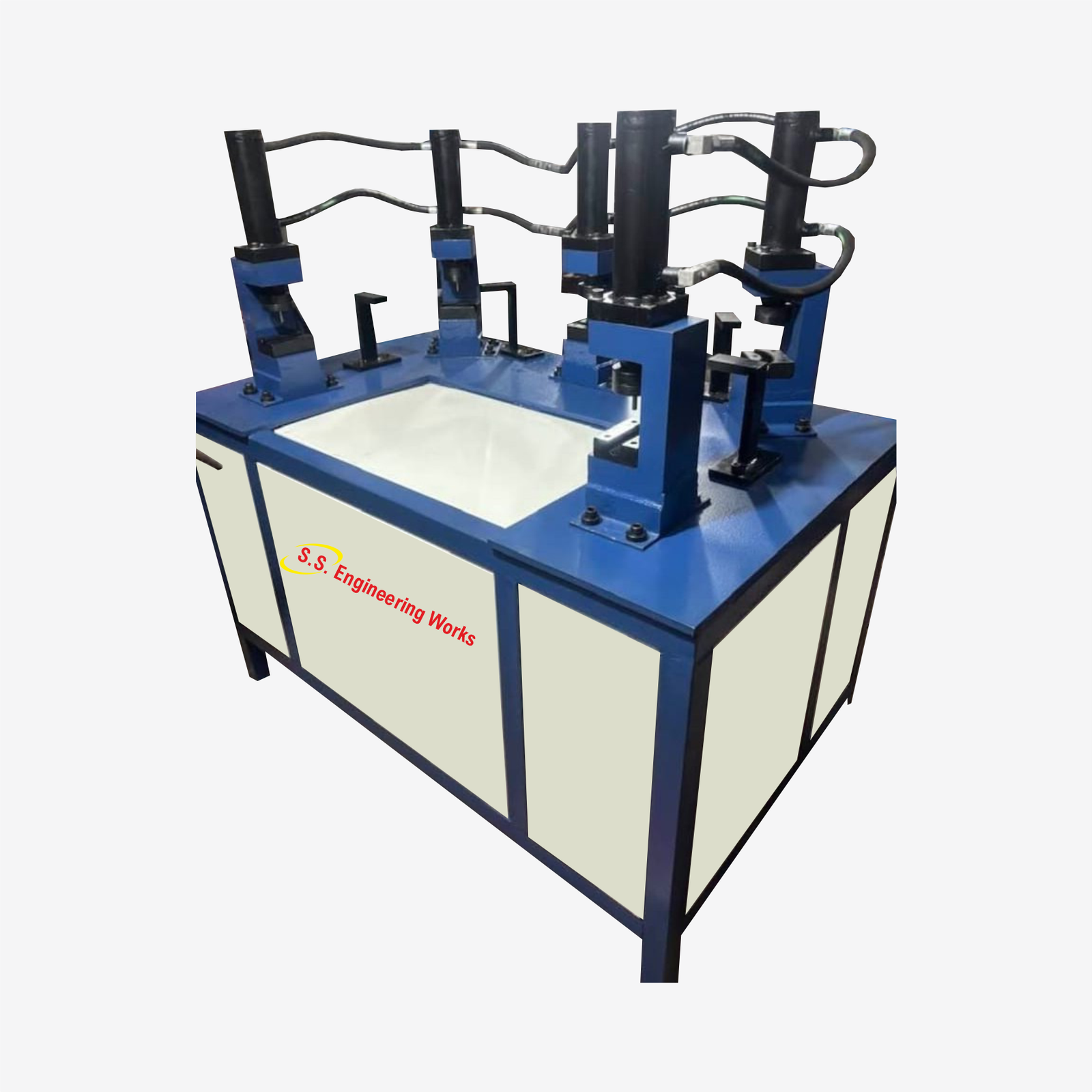

We specialize in designing and manufacturing tailor-made special purpose machines that cater specifically to your operational requirements, ensuring optimal performance for your unique processes.

Our team consists of highly skilled engineers and technicians with years of experience in the industry, providing you with innovative designs and reliable solutions based on proven methodologies.

We utilize the latest technology and techniques in both pneumatic and hydraulic systems to create efficient, high-performance machines that can improve productivity and reduce operational costs.

From initial consultation to after-sales service, we offer dedicated support at every stage of the project. Our team is always available to assist with maintenance and upgrades.

Beyond the initial sale, our support continues. We offer maintenance services, spare parts availability, and upgrades to ensure your machines operate at peak performance for years to come.

We adhere to strict quality control standards throughout the manufacturing process. Our machines undergo rigorous testing to guarantee durability, performance, and compliance with industry regulations.

Frequently Asked Questions?

We offer a variety of mould dies, including injection moulding dies, blow moulding dies, and extrusion dies. Each type is designed to meet specific manufacturing needs and is customized to fit our clients’ requirements.

Yes, we design and manufacture both pneumatic and hydraulic special purpose machines tailored to meet specific operational needs. Our team is experienced in creating solutions that enhance efficiency and performance in various applications, ensuring reliability and effectiveness in your production processes

We cater to a wide range of industries, including plastic manufacturing, chemical and pharmaceutical sectors, automotive, and general engineering. Our versatile capabilities allow us to provide solutions for various applications.

Quality is our top priority. We utilize advanced engineering technologies and quality control measures at every stage of production. Our experienced team is dedicated to delivering high-quality, precise products that meet industry standards.

The turnaround time can vary depending on the complexity and scale of the project. Generally, we strive to provide efficient service while maintaining quality. For specific timelines, we recommend contacting us directly to discuss your project requirements.